Concrete Hollow Square Pile Mould

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 3 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 3 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

Model No.: HH-KX350

Brand: Haiheng

250-700: Mm

| Selling Units | : | Set/Sets |

| Package Type | : | Nude Package |

The file is encrypted. Please fill in the following information to continue accessing it

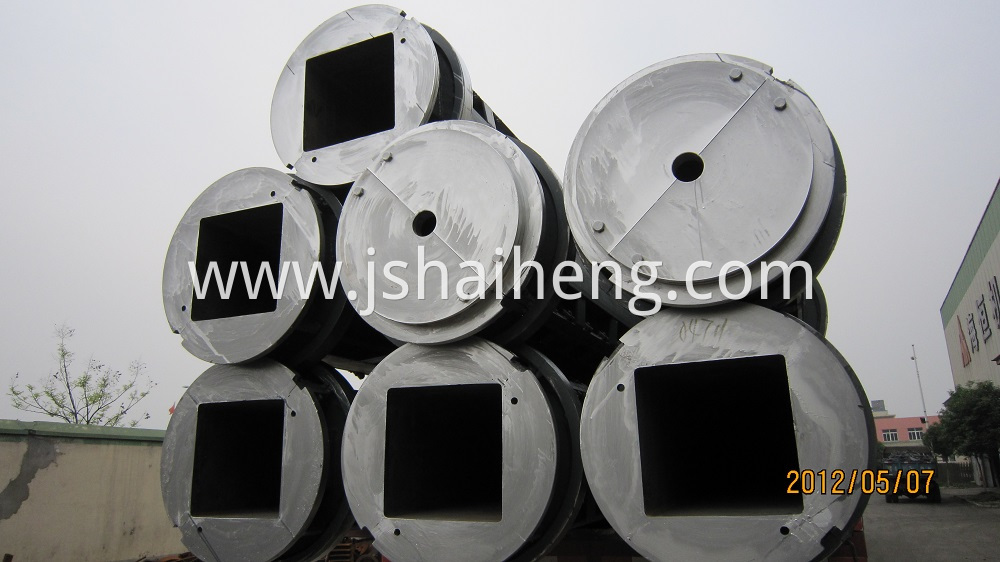

Concrete Hollow Square Pile Mould

Concrete Prestressed Hollw Square pile mould which is used to produce the hollow square pile, this kind of Hollow square pile in the process of production, it use tension prestressed, reperfusion concrete and then use Centrifugal Machine to spinning the water out, because of this processing that makes reinforced prestressed hollow square pile is higher than other type of pile, at the same time, the pile body used the high strength concrete (C60, C80), high strength steel and high strength concrete in the application of hollow square pile production, make the performance of the pile, the bearing capacity and crack resistance, bending resistance are obtained significantly higher.

Working Principle:

1. The steel prestressed hollow square pile mould should work together with Spun Pile Spinning Machine. The mould should be placed on the spinning machine smoothly.

2. Put the mixed concrete into the mould and rotate in different directions under the motor driven.

3. In this process, the redundant water in the concrete is released by the force of spinning, and the concrete's dense and inproved high strength. And then, the pile forms around the inner wall of the hollow square pile mould.

Mould Advantages:

1. Mould's tongue-and-groove is designed by the dislocation of upper and lower shell boards, matchboard is plane surface. Slurry does not leak and it is easy to clean mould.

2. The tyre is "T" type forgings. Tyre and its support plate are as whole.

3. Self-developed six-meter press machine of mould inside shell. The inside shell seam extends from two meters to six meters, to minimize welds and mould strength and improve the external appearance of the products

4. Welding process uses CO2 arc shield weld which makes its appearance simple and weld seam neat. Our company cooperated with colleges to introduce [robot welding project".

5. Long lathe, manufacture the whole set mould under fifteen-meter length, greatly increases concentricity of the tyre and flange.

If you have any questions, please contact with us directly. Haiheng Concrete Hollow Square pile Pile Moulds are produced by High Quality and Esay transportation, quick assembling, good rigidity and smooth working. Welcome you to visit our Factory.For inquiry,Please send mail directly to us.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.